Roth Poly Liner 1/8″ Thick

A super-slick, self-lubricating poly liner that resists wear, moisture, and bacteria

SKU:

Key Feature

Glassy surface prevents freezedown and material buildup

Product Features

- Self-lubricating

- Easy to install

- UV stabilized and resistant to chemicals and moisture

- Proven 20-year performance with no degradation

- Available in multiple thicknesses and widths for custom applications

- Saves feed costs, up to 1 lb. per cow daily

- Keeps feed fresher, reduces bacteria and mold

- Gentle on cows’ tongues, boosts intake and milk

- Easy cleaning, no scraping, quick sweep finish

Model

Uses

Lines mangers, conveyors, and equipment to extend life and improve performance

Ideal For

Mangers, feed bunks, conveyors, manure spreaders, and more

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Width

Length

Color

Price

Installation Instructions

- “Condition” poly at 45° or above (the hotter the better), for 24-hours prior to installation, to minimize future expansion. A heated milkhouse or direct sunlight works good. Elevate liner off cold floor/ground and unroll for quicker heat absorption. Weight-down liner to prevent it from rolling back up. Allowing the liner time to “relax” vs wrestling with a “springy” roll, will save you installation time.

- Predrill poly holddowns (3/8″ holes at 12″ intervals, starting 1″ from end).

- If holddowns not used, refer to note below.

- Thoroughly clean old feed, dirt and moisture from manger to prevent musty odors.

- If 1/8″ liner is used, fill in manger holes and rough spots with ready-to-mix concrete, sand, or lime; to provide flat, underlying support. Many farmers will fill in holes, even if 1/4″ liner is used, to prevent water from ponding under liner and possibly creating musty odors, or if liner is to be driven over. Some farmers drill 3/8″ to 3/4″ holes in low-lying portions of manger floor and under water bowls, straight down to gravel base, to permit drainage (refill holes with sand to aid drainage).

- Unroll liner and turn over so inside of roll faces up toward ceiling. Position liner in manger so joints, if any, are away from drinking cups and are between cows (you don’t want cows to lick over joints).

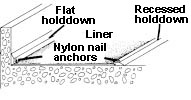

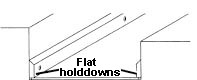

- On flat mangers, mount flat holddown flush over liner as illustrated below and lag holddown to curb, using an 1/4″ dia. x 2″ L nylon nail anchors (1-1/2″ L if cement is sound). See “Nylon Anchor” instructions. Also lag where cement is uneven for a tight fit. Butt ends of holddowns together (because of smaller temperature variations in barn), to prevent feed from accumulating in cracks. Mount recessed holddown over liner. Reposition liner under curb and feed-alley holddowns to allow for expansion/contraction (see “Expansion/Contraction” instructions). Lag same as curb holddown.

Flat Mangers

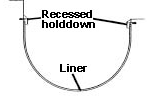

Round Mangers

Box Mangers

Curved Mangers

Frequently Asked Questions

- What’s the difference between poly liner rolls and sheets?

-

Poly liner rolls offer continuous coverage for long troughs or conveyors, while sheets are ideal for smaller, custom-cut applications such as barn liners or feed bunk liners.

- What’s the best liner for manure spreaders or conveyors?

-

A wear-resistant, self-lubricating HDPE poly liner is best for manure spreaders and conveyors, offering long-lasting protection and reduced maintenance. Size wise, for manure spreaders: 3/16" on the bottom and typically 1/8" on the sides and for conveyors: 1/4" is recommended.

- What width and length options are available for poly liner rolls?

-

Poly liner rolls are available from 24" to 48" in width and 10' to 100' in length to suit different applications, from narrow auger troughs to wide feed bunk liners.

- What makes a poly liner self-lubricating and how does it reduce energy use?

-

Self-lubricating poly liners reduce friction between moving parts, lowering energy consumption in equipment like conveyors and manure spreaders.

- What is a poly liner and where is it used?

-

A poly liner, often made from HDPE or polyethylene, is a durable sheet used to line surfaces in agricultural equipment such as barn liners, feed bunks, and manure spreaders to reduce wear and improve cleanliness.

- What are the benefits of using a polyethylene liner in livestock equipment?

-

Polyethylene liners offer chemical resistance, noise reduction, and a self-lubricating surface that reduces friction and wear in livestock equipment like feed bunks and auger troughs.

- Is a UV-stabilized liner necessary for outdoor applications?

-

Yes, UV-stabilized poly liners are recommended for outdoor use to prevent degradation from sunlight, especially in exposed barn liners and feed troughs.