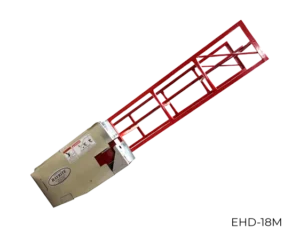

Roth Galvanized Conveyors 9″ Width

Heavy-duty single-chain conveyor with wider flights and smoother operation – 9″ Width

Call for anything over 32′ Length.

Product Features

- Full-width cross shaft and chain final-reduction drive

- Heavy-gauge pan and steel flights for durability

- Ships in one piece up to 12′ for easy setup

- Compatible with electric motors and accessories

- Designed for low-maintenance, long-term use

Model

Uses

Moves feed, silage, grains, and other materials efficiently

Ideal For

Farms handling silage, haylage, grains, manure, and other loose materials

Effective Length

6'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

8'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

10'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

12'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

14'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

16'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

18'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

20'

Pan

14 ga.

Trough

16. ga.

Pintle Chain No.

662

Effective Length

22'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

24'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

26'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

28'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

30'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Effective Length

32'

Pan

14 ga.

Trough

16 ga.

Pintle Chain No.

662

Product Resources

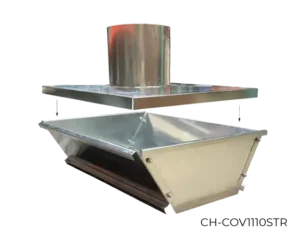

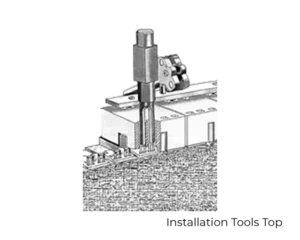

Accessories

Frequently Asked Questions

- Can the conveyor be customized?

-

Yes, the galvanized conveyor offers a wide choice of lengths and accessories including, motors, and covers.

- Is the conveyor chain easy to adjust?

-

Yes, the galvanized conveyer includes a bolt-type take-up at the discharge end, allowing up to 2" of adjustment with just a few turns of two nuts.

- What makes the Roth single-chain conveyor durable?

-

The galvanized conveyer is built with heavier-gauge, rust-resistant galvanized steel that resists forage acids for longer life.

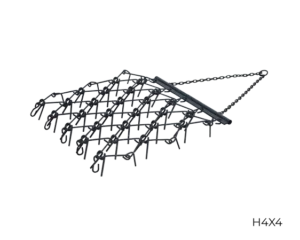

- What helps prevent material buildup in the sprockets?

-

The galvanized conveyer uses heavy cast-iron sprockets designed to prevent material buildup between the chain and sprocket.

- What is the benefit of the enclosed lower trough?

-

The galvanized conveyer’s enclosed lower trough ensures clean chain return and adds extra structural strength.

- What kind of connecting joints are used?

-

The galvanized conveyer uses sturdy angle iron connecting joints that prevent bowing and twisting, and are easy to bolt together.

- What elevator widths are available for the galvanized conveyer?

-

The galvanized conveyer is available in 9" and 11" widths to match different material handling needs, including silage, haylage, grains, and more.

- What type of chain is used in the conveyor?

-

The galvanized conveyer uses sturdy, detachable or pintle conveyor chain that is tempered hard for longer wear.

- What’s the best liner for manure spreaders or conveyors?

-

A wear-resistant, self-lubricating HDPE poly liner is best for manure spreaders and conveyors, offering long-lasting protection and reduced maintenance. Size wise, for manure spreaders: 3/16" on the bottom and typically 1/8" on the sides and for conveyors: 1/4" is recommended.